Protect Your Most Valuable Assets

Continuous maintenance of your equipment is key to keeping your most valuable assets up and running for long-term use. But in the hustle of managing multiple job sites, it can easily fall to the wayside–especially if you are still keeping tabs on your equipment with spreadsheets and notepads.

The AlignOps platform simplifies your equipment maintenance program to keep your machines serviced and your projects moving forward to ensure you get strong ROI on your assets.

Here are three ways AlignOps empowers you to streamline your equipment service and calibration workload:

Schedule Service Plans for Equipment

Your equipment is likely some of your company's most expensive assets, so you must service them according to manufacturer-recommended maintenance plans and in compliance with OSHA-required safety inspection schedules.

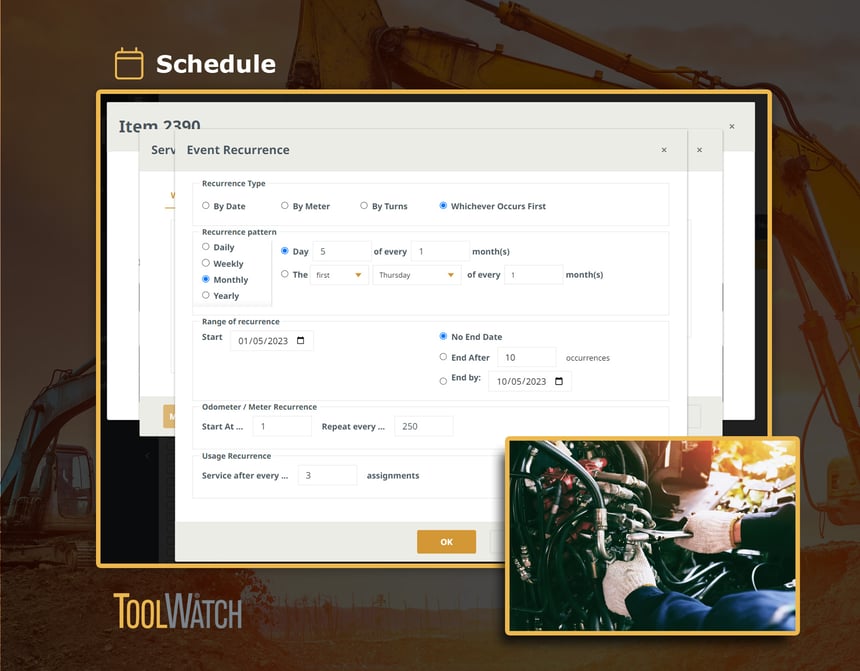

AlignOps enables you to create a service plan to keep your equipment in good working order and compliant with regulations. By scheduling your service reminders within AlignOps, you can ensure your assets get the service, inspections, and calibrations required to run smoothly, remain compliant and deliver maximum value to your projects and business.

Automate Your Service Notifications

With AlignOps, you’ll automatically receive notifications when your equipment is due for maintenance events, safety inspections, and calibrations—no more manual tracking. This means you can rest assured that your equipment has been inspected on time and properly maintained by qualified personnel.

From day one, your entire service history is available so you can confidently know that inspections have been completed on time.

Track Your Complete Service History

Broken equipment is a big problem on the job site. Not only is it often expensive to fix these assets, but equipment breakdowns also affect your team’s ability to deliver projects on time.

But on the other hand, we know how difficult it can be to keep track of equipment service records and monitor the issues that arise after long-term use, especially when you’re focused on completing the project at hand.

AlignOps makes it easier for you to capture and audit the complete service history of your assets. Keep track of every service event, who completed the service, where it is currently being stored, and even where it has been in the past.

Real World Success Story

Gastier, a leader in the Quebec construction industry, faced significant operational challenges before AlignOps, including challenges in effectively managing and maintaining their equipment. AlignOps has been a game changer for Gastier, preventing breakdowns and proactively monitoring expiration dates for equipment. This case study explains how AlignOps powers Gastier’s construction operations.

Acquiring & Managing Equipment Assets

Get an inside look into the challenges, trends, and solutions impacting how companies acquire and manage equipment by watching our on-demand webinar, "Managing & Financing Construction Assets in Uncertain Times."

Ready to get the most out of your heavy equipment? Learn more about AlignOps's equipment capabilities today.

-x2(2732x988).jpg?width=960&length=960&name=warehousemobile-hero-mid-long-bg-x1(1366x494)-x2(2732x988).jpg)